Professional Paper Container Forming Machine Manufacturer & Production Line Solution Provider

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

KH-SK108 Paper Cup Sleeve Machine

|

|

Brief Description

The KH-SK108 intelligent paper cup sleeve machine adopts cylindrical cam, gear transmission, and vertical axis structure, thereby reasonable distribution of each functional assembly. The whole machine is lubricated by oil spray lubrication. Electric is controlled by PLC. Suitable for the production of 8-16oz double wall paper cups, it is an ideal equipment to make the thermal insulation or decorative sleeves for milk tea cups, instant noodle cups, coffee cups, corrugated cups and others.

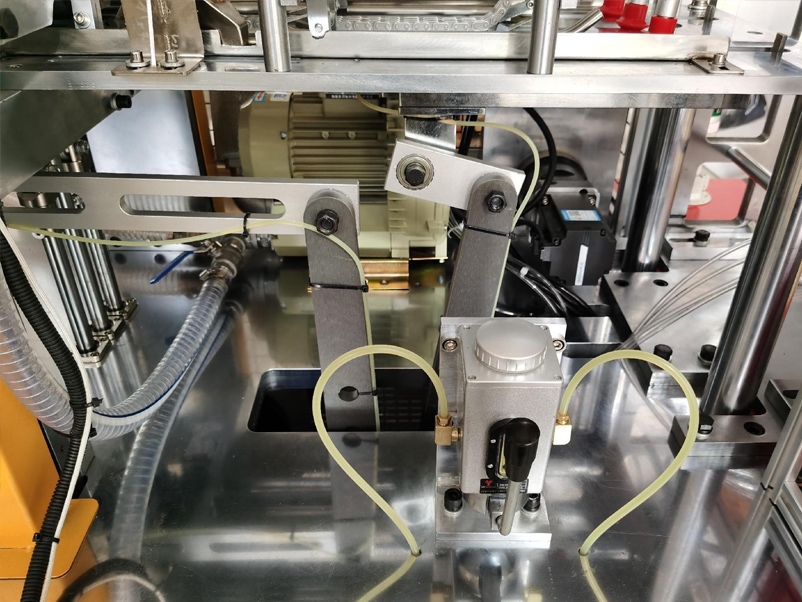

1.The machine adopts automatic oil spray lubrication to reduce mechanical wear, improve heat dissipation performance, and ensure efficient and long-lasting operation of the transmission.

2.The transmission adopts a vertical axis gear structure, an inverted cylindrical follow-up indexing cam mechanism and gear transmission, which optimizes the internal layout, ensures the synchronous transmission accuracy of the machine, and ensures the stability and quality of the whole machine.

3.The electrical components adopt PLC programmable logic controller, photoelectric tracking and servo, endowing the machine with self-monitoring and intelligent operation.

(Note: During the production process, any adjustments, optimizations and upgrades made by the manufacturer based on the improvement of product quality or the original technology and related configurations of machine manufacturing are all reasonable changes in the production process of the machine without prior notice.)

Main Technical Specification

Model | KH-SK108 High Speed Intelligent Paper Cup Sleeve Machine |

Cup forming size | 8-16 oz Top diameter: ф70-95mm Height: 70-137mm Bottom diameter: ф50-75mm Bottom depth: 5-12mm |

Paper thickness and type | 0.282-0.50mm 190-350gsm 1-sided PE coated gray-back or white-back white cardboard paper chosen as the best |

Capacity | 90-115 pcs/min |

Required compressed air | 0.6-0.8MPa,0.4m³/min |

Power source | 3-Phase 4-Wire 380V 2.5KW (Working power) / 5KW (Total rated power) |

Machine size | 1100 x 1100 x 1800mm Cup collection table |

Machine weight | 2200 KG |

Note: Machines are being improved constantly, configuration is subject to the latest design and technology. Minor configuration changes are subject to change without notice.

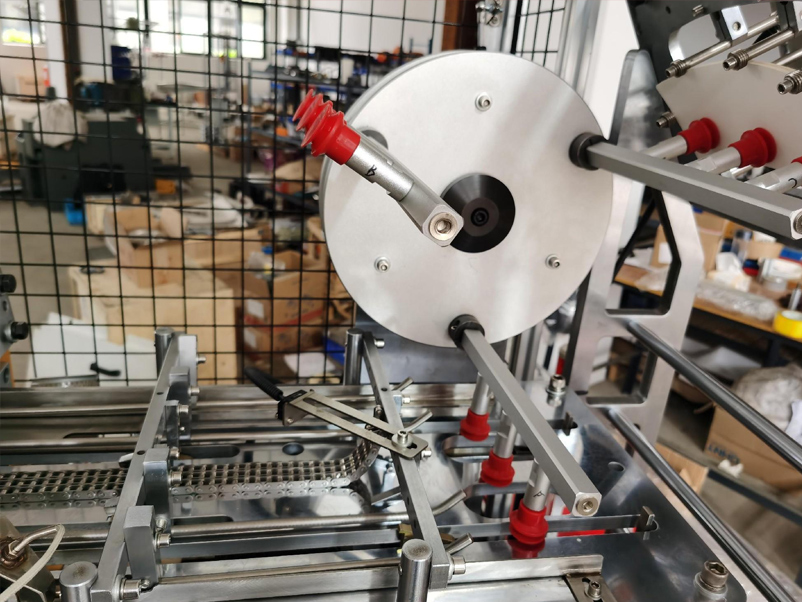

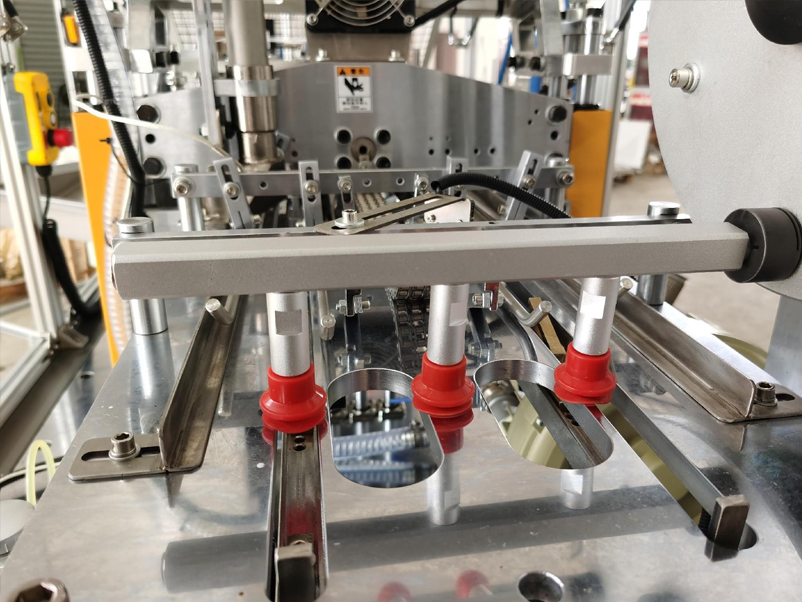

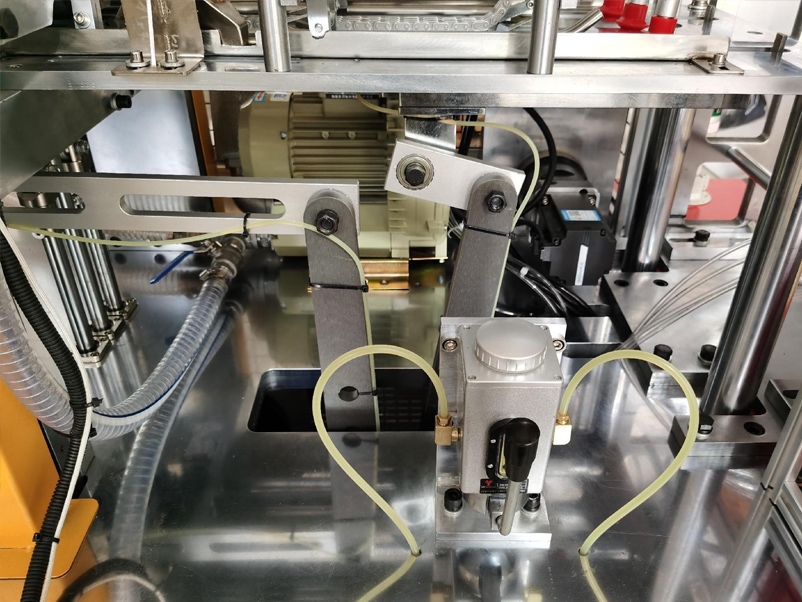

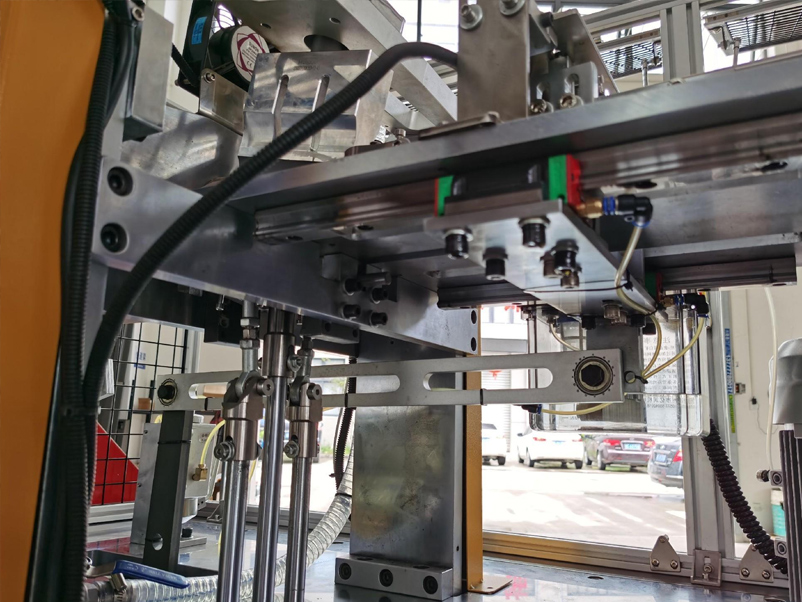

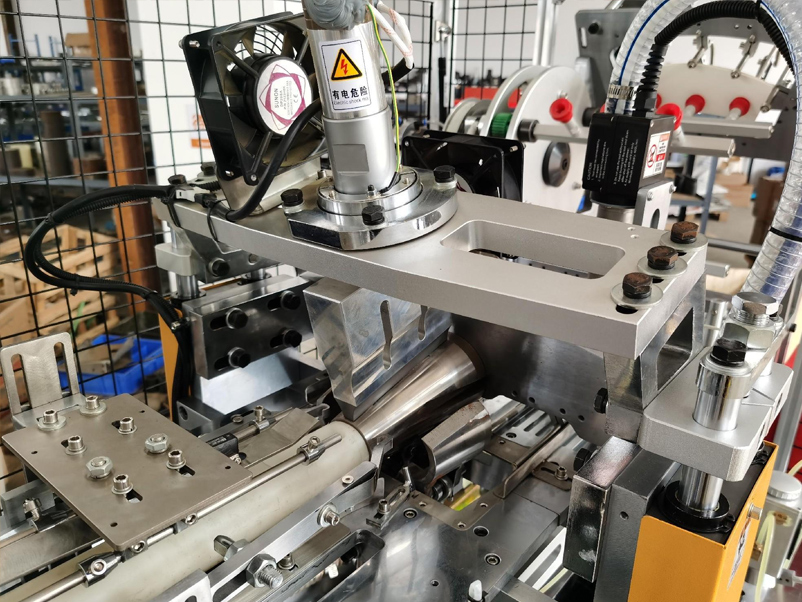

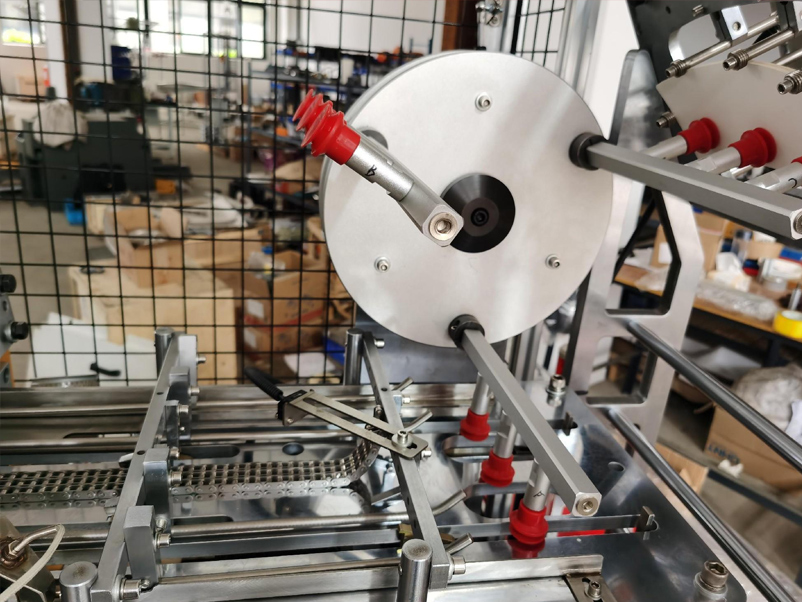

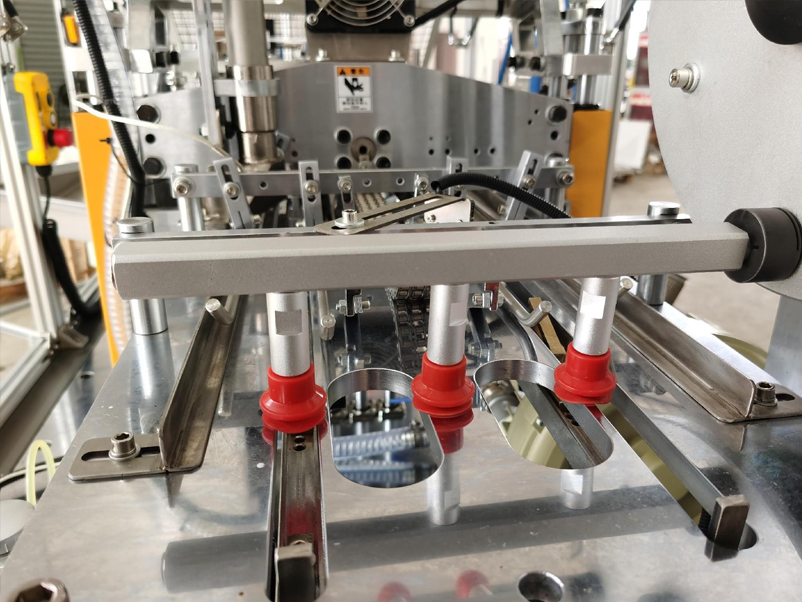

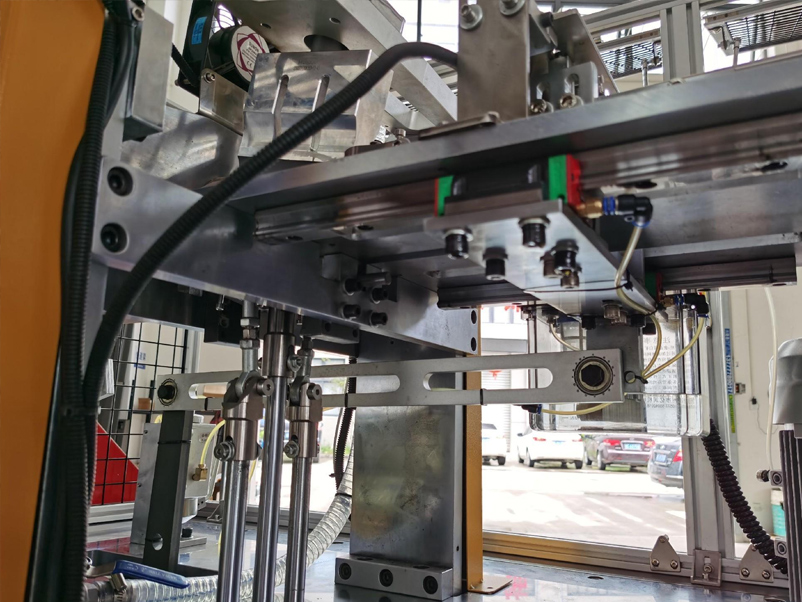

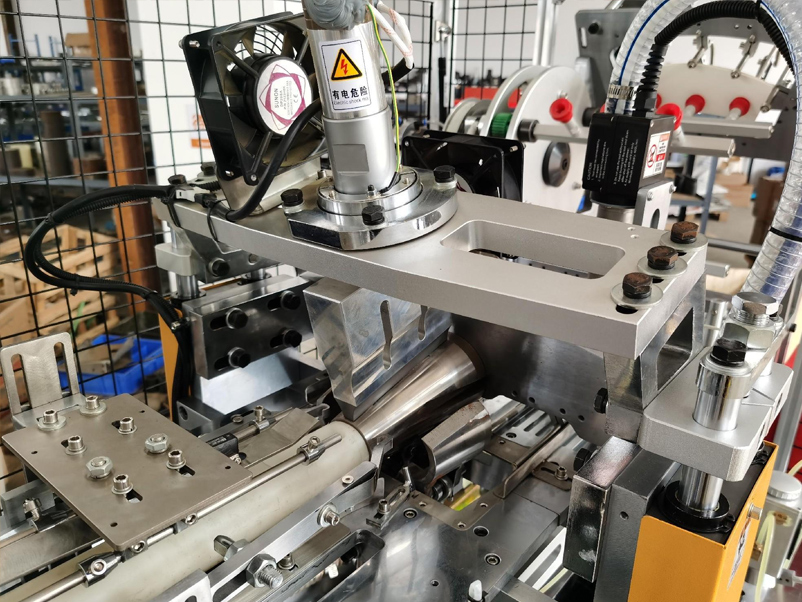

Machine details

|  |  |

|  |  |

|  |  |

KH-SK108 Paper Cup Sleeve Machine

|

|

Brief Description

The KH-SK108 intelligent paper cup sleeve machine adopts cylindrical cam, gear transmission, and vertical axis structure, thereby reasonable distribution of each functional assembly. The whole machine is lubricated by oil spray lubrication. Electric is controlled by PLC. Suitable for the production of 8-16oz double wall paper cups, it is an ideal equipment to make the thermal insulation or decorative sleeves for milk tea cups, instant noodle cups, coffee cups, corrugated cups and others.

1.The machine adopts automatic oil spray lubrication to reduce mechanical wear, improve heat dissipation performance, and ensure efficient and long-lasting operation of the transmission.

2.The transmission adopts a vertical axis gear structure, an inverted cylindrical follow-up indexing cam mechanism and gear transmission, which optimizes the internal layout, ensures the synchronous transmission accuracy of the machine, and ensures the stability and quality of the whole machine.

3.The electrical components adopt PLC programmable logic controller, photoelectric tracking and servo, endowing the machine with self-monitoring and intelligent operation.

(Note: During the production process, any adjustments, optimizations and upgrades made by the manufacturer based on the improvement of product quality or the original technology and related configurations of machine manufacturing are all reasonable changes in the production process of the machine without prior notice.)

Main Technical Specification

Model | KH-SK108 High Speed Intelligent Paper Cup Sleeve Machine |

Cup forming size | 8-16 oz Top diameter: ф70-95mm Height: 70-137mm Bottom diameter: ф50-75mm Bottom depth: 5-12mm |

Paper thickness and type | 0.282-0.50mm 190-350gsm 1-sided PE coated gray-back or white-back white cardboard paper chosen as the best |

Capacity | 90-115 pcs/min |

Required compressed air | 0.6-0.8MPa,0.4m³/min |

Power source | 3-Phase 4-Wire 380V 2.5KW (Working power) / 5KW (Total rated power) |

Machine size | 1100 x 1100 x 1800mm Cup collection table |

Machine weight | 2200 KG |

Note: Machines are being improved constantly, configuration is subject to the latest design and technology. Minor configuration changes are subject to change without notice.

Machine details

|  |  |

|  |  |

|  |  |